Hysata is a green energy start-up based in Port Kembla. Bringing down the cost of clean hydrogen, their technological breakthrough is helping accelerate the shift away from fossil fuels in the world’s push toward net-zero targets.

Hydrogen offers a clean alternative to fossil fuels like coal and diesel for organisations looking to reduce their carbon footprint. When it comes to heavy industry, hydrogen has the potential to power everything from heavy-duty trucking fleets to steel blast furnaces and chemical manufacturing plants.

Hydrogen is created using an electrolyser, which uses electricity to split water into hydrogen and oxygen. The challenge is doing this in an energy-efficient, low-cost and environmentally-friendly way.

Chief Executive Officer, Paul Barrett said "Green hydrogen will play a critical role in decarbonising hard-to-abate sectors such as steel, chemical manufacturing and heavy transport. But to make it a reality it needs to be a cost-effective solution."

Using renewable electricity ensures that the hydrogen is ‘green’, or environmentally friendly, but traditional electrolysers only offer around 75% energy efficiency. A quarter of the electricity goes to waste, which drives up costs and makes hydrogen a less competitive alternative to fossil fuels.

Hysata has addressed this challenge with its next-generation electrolyser, which boosts energy efficiency to 95% to become the world's most efficient electrolyser.

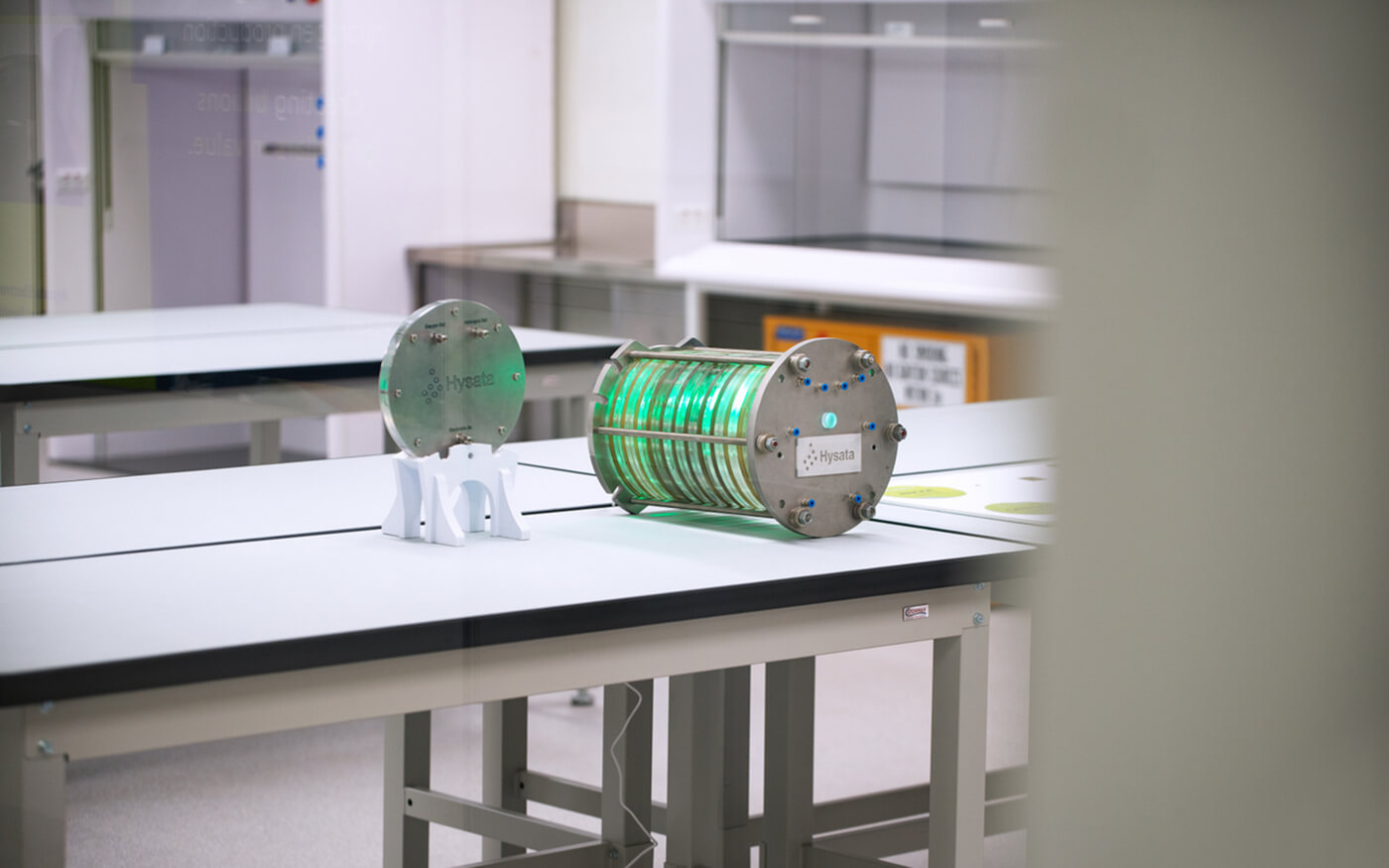

Spun out of the University of Wollongong, Hysata has developed a 'capillary-fed' electrolyser. An electrolyser splits water into hydrogen and oxygen. In traditional designs, gas bubbles crowd the electrode, and reduce the electrolyser efficiency. Hysata's design uses a sponge membrane to achieve direct delivery of water to electrodes and eliminates bubble formation.

The new electrolyser's ultra-high efficiency means its operating infrastructure is more simplified, delivering additional cost savings.

Thanks to these innovations, Hysata's electrolyser only uses 41.5 kilowatt hours (kWh) of electricity to produce 1 kilogram (kg) of hydrogen, beating the target of 45 kWh set by the International Renewable Energy Agency for 2050.

Hysata's technology is well-suited to commercialisation, thanks to low equipment costs and a modular design which can easily be scaled up. As a result, it has the potential to produce hydrogen at less than $2 per kg, which is around half of today's cost.

The NSW Government has granted Hysata $1.5 million to pilot a 200-kilowatt electrolyser stack at its Port Kembla electrolyser manufacturing facility. The funding will help Hysata progress the product development of its high efficiency electrolyser.

Green hydrogen is expected to supply 10 to 15% of the world's energy needs in a net-zero global economy. Hysata's electrolyser technology is putting Australia at the forefront of the green energy revolution, said Paul.

"By progressing both our technology and commercial readiness, the NSW Government funding is playing an important role in ensuring that Hysata and NSW are helping Australia lead the world," Paul said.

Next, Hysata will develop and manufacture a 5-megawatt capillary-fed electrolyser, to be shipped to Queensland's Stanwell Power Station for a field test in 2025. Going forward, Hysata already has tentative deals in place for 9.4 gigawatts’ worth of electrolyser sales, thanks to signed conditional orders and letters of intent from customers.

"Scaling Hysata's electrolyser manufacturing is critical to developing domestic manufacturing and green hydrogen sovereign capabilities," Paul said.

"Unlocking the full potential of green hydrogen sets the world on the right path to decarbonising heavy industry and meeting global net-zero targets."

If you enjoyed this story, read our story about The Melt – a hardware accelerator that is helping transform the Hunter into a clean energy super precinct. You can also sign up for our newsletter to receive updates including our round 2 grants.